1、Generally, the water injection pumping process of the oilfield water injection station mostly uses the traditional water source which pump water to the large storage tank, and then the feed water pump supplies the water from the water storage tank to the water injection pump. Finally, the water injection pump injects water into the formation.

Most of the motors of the water injection pump are high-power motors (110, 185kW). The outlet pressure of the water injection pump is usually realized by adjusting the valve. The operators adjust the valve by observing the pressure of the pressure gauge at any time, while basically the rated speed of the pump motor remains unchanged.

In this way, for the electric motor, the phenomenon of the big horse-drawn car is very serious, the pipe network pump is more, and the process is complicated, which wastes electric energy and increases the labor intensity of the operator. The VFD constant pressure water supply control system is used to realize the stepless speed regulation of the pump motor. The operating parameters of the system are automatically adjusted according to the requirements of the water injection pressure, and the water pressure of the pipe network is kept constant when the water consumption changes to meet the water injection requirements.

Variable frequency speed control system is an advanced and reasonable energy-saving water supply system, the practical application has been developed greatly, with the rapid development of power electronics technology, the function of the VFD is becoming stronger and stronger, making full use of the various functions of the VFD, the application of constant voltage variable frequency water supply system has vital significance.

2、The application of TORRIVE VFD

The variable frequency speed control system device adopts the TORRIVE frequency converter as the main control device, and the 4-20 mA signal is collected by the pressure transmitter and transmitted to the VFD PID controller to monitor the pressure change of the water supply and the water injection pipe network, and the frequency converter is controlled. The output frequency adjusts the operating state of the pump to maintain the network pressure within a constant pressure range.

The motor power of the deep well pump of the water source well is 5.5kw, driven and controlled by a 7.5kw VFD.

Injection pump motor power is 110 kw (185 kw), controlled by 132 kw (200 kw)VFD , in accordance with the requirements of different water amount and pressure, the variable frequency operation and standby power frequency to realize the constant water pressure, the system set the PID controller parameters, according to the frequency display, pressure, under-voltage timeout, water pressure on indication and alarm, the lower pressure to the operation of the control system.

Install a pressure transmitter on the inlet pipe before the water injection pump to control the operation of the deep well pump VFD; install a pressure transmitter on the outlet pipe of the water injection pump to control the operation of the water pump VFD and control the VFD output frequency. The size of the pump changes the speed of the pump to achieve a constant pressure control network.When the actual pipe network pressure is less than the given pressure value, the output frequency of VFD rises, the speed of motor increases, and the pressure of pipe network starts to rise; On the contrary, the frequency of the VFD is reduced, the speed of motor is decreased, and the pipe network pressure is dropped. Through automatic adjustment, the system keeps the actual pressure constant around the set pressure. The frequency conversion speed regulation control system forms the controllable parameter closed loop control in the pump operation process, implements the constant pressure water supply, maintains the water injection system and the dosage in the equilibrium state, realizes the automatic control.

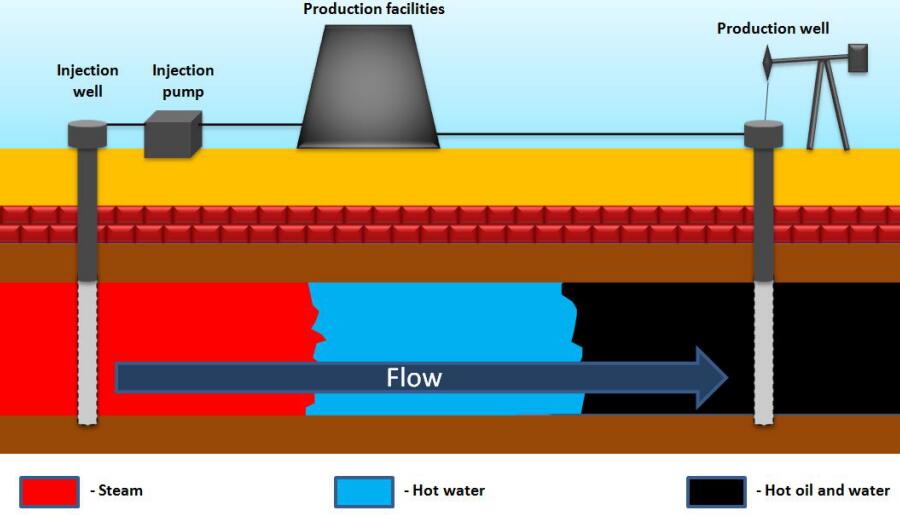

In the past, the process of water injection pump was: water source well - water storage tank - feed pump - water injection pump.

Variable frequency speed control system is installed, and the process can be simplified as: water source well - water injection pump through constant pressure water supply control.

This technical innovation simplifies the technical process, reduces the operation steps and the times of start and stop of water source well , realizes the automatic water supply, which can effectively restrain the big horse cart phenomenon, existing in the pump operation, it not only reduces the operator's labor intensity, but also can save the electric energy.

2、Schematic diagram of variable frequency speed control system

The working principle of the whole equipment control system is as follows:

The pressure of the water supply pipe network collects feedback signals through the pressure transmitter, and then the set value and the collected deviation signal value are compared through the A/D conversion module of the frequency converter through PID control. PID processes the data according to the parameter setting of the frequency converter, and outputs the processing results in the form of operating frequency.

PID control module has the function of comparison and difference. If the pressure of water supply pipe network is lower than the set pressure, the frequency converter will increase, and vice versa.

And the differential adjustment according to the speed of the pressure change, taking the negative action as an example: if the pressure rises too close to the set value, the rising speed is too fast, the PID operation will also reduce the execution amount, thereby stabilizing the pressure. Under the PID control, a 4 mA corresponds to 0 MPa, 20 mA corresponds to 1 MPa pressure transmitter to adjust the water supply pressure of the water source well deep well pump, and another 4 mA corresponds to 0 MPa, 20 mA corresponds to 25 MPa pressure transmitter to adjust the water injection pressure of the water injection pump. The set value is given by the inverter terminal (0 to 10V).

During the whole operation, when there is a lack of phase, under-voltage, frequency converter fault, over-pressure , and so on , the system can make a sound alarm signal, especially when there is a lack of phase, VFD fault, over-pressure, the system will automatically stop, and signal alarm, maintenance personnel maintenance process in time, so that it is back to normal.

In addition, when the VFD fails, the system can be switched to manual mode, and the system can be operated in the mode of backup and power frequency to ensure water injection production.

The soft start function of the VFD also reduces the impulse current when the equipment motor starts, thus effectively protecting the equipment, power grid and so on, and extending the service life of the equipment.

3、Popularization range: all pump loads, such as water injection pumps, oil pumps, hot water pumps, deep well pumps, blowers, etc.